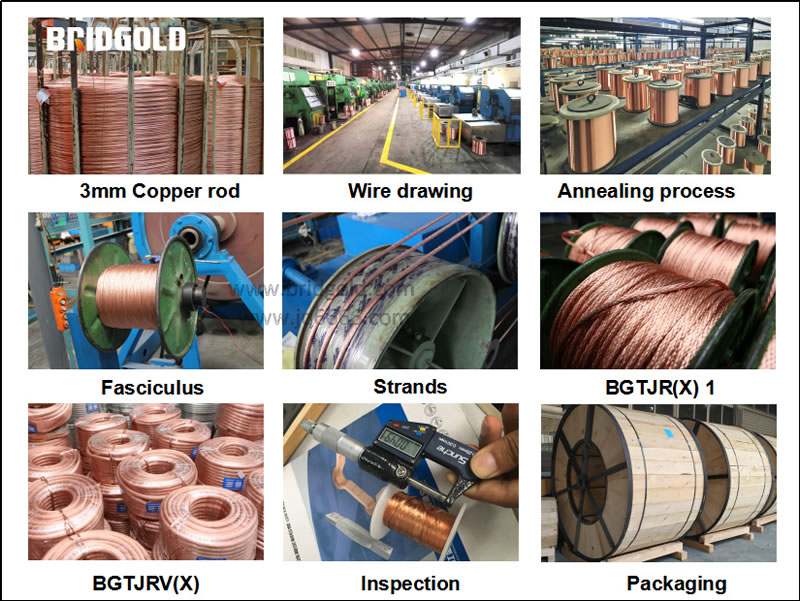

Production Process of Copper Stranded Wire

Copper stranded wire is suitable for electrical equipment, electronic appliances or component wiring or copper stranded wire used in these occasions is at flexible connecting wire for electrical devices (such as transformers, electric furnaces) and electronic and electrical equipment for power transmission and distribution, and SCR components. Copper stranded wire is made of high-quality round copper wire or tinned soft round copper wire. Toughened during the processing process, the finished product is flexible and the appearance is neat and beautiful.

The DC resistance (20°C) of the copper stranded wire is not greater than 0.0182Ω.mm^ 2 / m; the DC resistance (20°C) of the tinned copper stranded wire is not greater than 0.0193Ω.mm^ 2 / m. Copper stranded wire is a flexible connecting wire for electrical equipment and electronic appliances or component wiring.

The basic processing flow of bare copper stranded wire: copper rod → copper rod inspection (according to GB/T3952-2008 copper wire blank for electrical engineering) → wire drawing (large drawing machine) → medium and small drawing (continuous continuous or tank annealing) → Strands (tube stranding machine or wire stranding machine) → Conductor stranding (tube stranding machine, cage stranding machine, requiring back-twisting) → Finished product inspection (according to standard GB12970.2-2009) → Packaging → Storage.