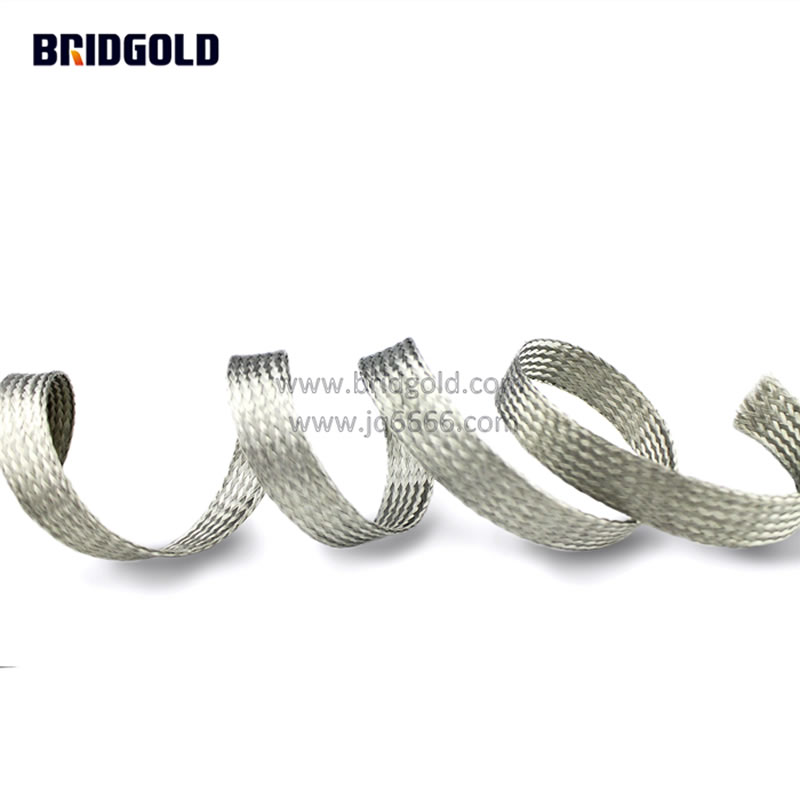

The Technical Standard of Flexible Copper Braids

Technical standard of flexible copper braids: braided with tinned T2 oxygen-free copper wire, divided into soft and hard varieties, bright and soft, reliable quality and complete specifications. The product is corrosion-resistant, smooth and beautiful in appearance, which can improve the pressure bearing of the finished hose, high and low temperature resistance, extend the service life of the pipe body, reduce costs, and is widely used in machinery, chemical, metallurgy, construction and other industries.

The basic standards are as follows:

- Basic performance: It has good scalability, can be large or small, has good protection for the wire, wear resistance, to prevent the wire from being cut and scratched, and has a wire harness shielding effect.

- Wear resistance: It can effectively prevent the power jacket from being cut or damaged, and effectively protect the power supply.

- Expansibility: It can be used for various regular or irregular shaped wires. The diameter of the network tube can change with the diameter of the wire (generally up to 1-3 times).

Our standards are different on different equipment, no matter the size or load current have different requirements, so it is difficult to have a standard for your reference. When purchasing copper flexible connecting conductive tapes such as flexible copper braids, our standard is the size of your installation, the size of the current and the use environment to provide you with the corresponding products, giving you the most suitable option.